Used carton flow rack is an American Surplus specialty. Our used flow racks are stored indoors in our 530,000 square foot warehouse. Custom flow rack sizes are available at 50% off retail prices. American Surplus guarantees the lowest carton flow rack prices. Our used carton flow rack is made to order, and is half the price of new flow rack. Best Price Guaranteed. Same Day Quote.

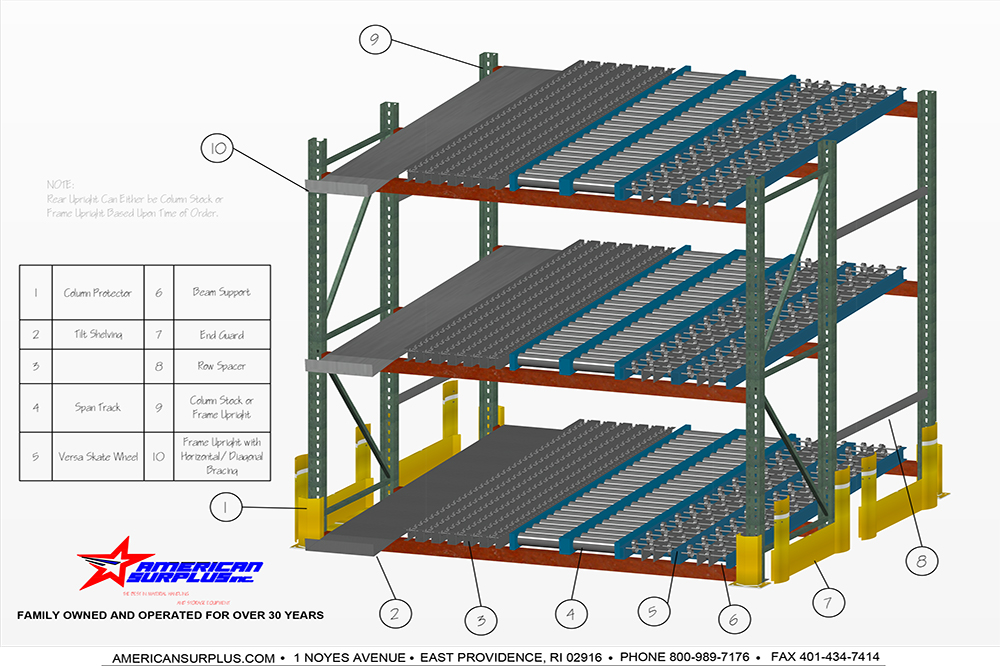

Carton flow rack can be stand-alone units or placed into pallet rack to create a high-density storage system. Carton flow rack, combined with accumulating conveyor, is designed to meet the customers' inventory needs. The dimensions of the system are determined by the product sizes and weights. Shelves and trays are adjustable to provide access to various size cartons.

American Surplus carries every leading manufacturer of used carton flow rack available, including: Kenneco, Kingway, Hytrol, Interlake, and Quick Pick flow rack and span track. Flow rack may also be referred to as: case flow rack, span track flow rack, picking rack system, zone picking flow rack, used pick system, pick modular flow rack, or carton flow rack.

Carton flow rack is a style of racking that uses a rear load design. Shelves are set at a slight pitch and contain wheels to allow for products to slide to the front of the racking automatically. When a stored item is removed from the front, the item directly behind it slides in to replace it. This keeps merchandise better organized and easier to pick because it reduces the amount of additional labor required when picking and stocking.

Gravity flow rack utilizes a first in, first out (FIFO) dynamic style of inventory management. This is because product is loaded into the rear of the rack and then slides to the front where it is first to get picked. Because only the front-most product can be picked, it is recommended that you store like items in a single row. This helps keep product organized and makes quick inventory spot checks very easy to accomplish.

It is considered dynamic because it is stocked from the back and picked from the front, which allows for no interference when both functions are being performed simultaneously. It also minimizes travel when performing either function.

Why buy used carton flow rack? This style of racking can be very expensive, especially when buying new. We primarily deal with used at ASI and can provide you used gravity flow rack systems at a fraction of the cost of new. All our used material handling equipment is in great working condition. Our friendly and knowledgeable sales staff will work with you to help provide solutions for your material handling problems.