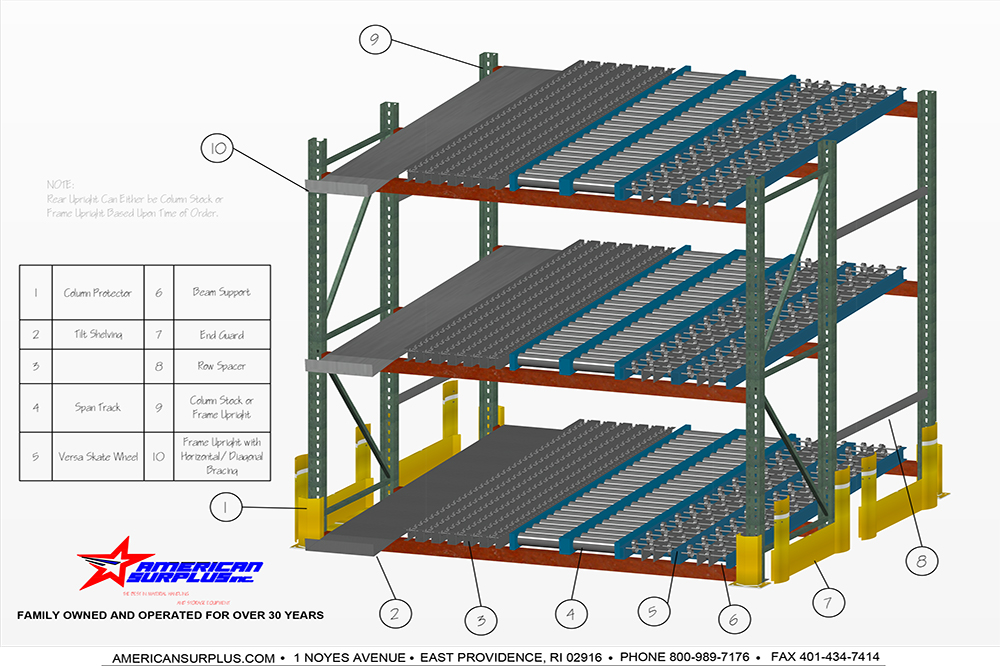

New Carton Flow Rack can be stand-alone units or placed into pallet rack to create a high-density storage system. Carton flow rack, combined with accumulating conveyor, is designed to meet the customers' inventory needs. The dimensions of the system are determined by the product sizes and weights. Shelves and trays are adjustable to provide access to various size cartons.

One of the key features of a new carton flow rack is its ability to facilitate the efficient movement and retrieval of cartons or boxes within a storage system. The system typically consists of inclined roller or wheel tracks that allow cartons to flow smoothly from the loading end to the unloading or picking end under the influence of gravity. This promotes the first-in, first-out (FIFO) inventory management method, ensuring that older inventory is picked before newer stock, which is crucial for products with expiration dates or strict inventory rotation requirements.

Carton flow rack is a style of racking that uses a rear load design. Shelves are set at a slight pitch and contain wheels to allow for products to slide to the front of the racking automatically. When a stored item is removed from the front, the item directly behind it slides in to replace it. This keeps merchandise better organized and easier to pick because it reduces the amount of additional labor required when picking and stocking. Flow can double the inventory storage of standard selective rack and do it with a smaller, compressed footprint. It’s a compact storage solution that can go exceptionally deep depending on inventory needs.

Carton flow rack utilizes a first in, first out (FIFO) dynamic style of inventory management. This is because product is loaded into the rear of the rack and then slides to the front where it is first to get picked. Because only the front-most product can be picked, it is recommended that you store like items in a single row. This helps keep product organized and makes quick inventory spot checks very easy to accomplish.

It is considered dynamic because it is stocked from the back and picked from the front, which allows for no interference when both functions are being performed simultaneously. It also minimizes travel when performing either function.

In addition to optimizing order picking processes, a new carton flow rack can help maximize storage space utilization, reduce labor costs, and enhance inventory visibility. Businesses seeking to improve their warehouse or distribution center operations may consider implementing a new carton flow rack system to meet their storage and order fulfillment needs efficiently and effectively.

Call our sales team today to determine which style of flow rack is right for you. They will consider everything from the types of materials you will be storing, to the size of your facility and make a recommendation based on your specific storage needs.