New Teardrop pallet racks are a versatile and popular solution for efficient and organized storage in various industrial and commercial settings. Known for their distinctive teardrop-shaped holes on the upright frames, these racks offer easy assembly, adjustability, and compatibility with a wide range of accessories. They provide a cost-effective means of maximizing storage space, making them a preferred choice for businesses looking to optimize their inventory management. Whether in warehouses, distribution centers, manufacturing facilities, or retail stores, new Teardrop pallet racks offer durability, versatility, and customization options to suit specific storage needs, making them a go-to solution for modern businesses striving for efficient and safe warehousing practices.

American Surplus Inc. is a well-known company specializing in the sale of new and used material handling equipment and storage solutions, including teardrop pallet racks. This allows customers to choose between cost-effective, pre-owned systems and brand-new equipment, depending on their budget and specific needs. eardrop pallet racks are available in various sizes and configurations to accommodate different storage requirements. American Surplus Inc. often provides a selection of options to fit the space and product dimensions of your warehouse or storage facility.

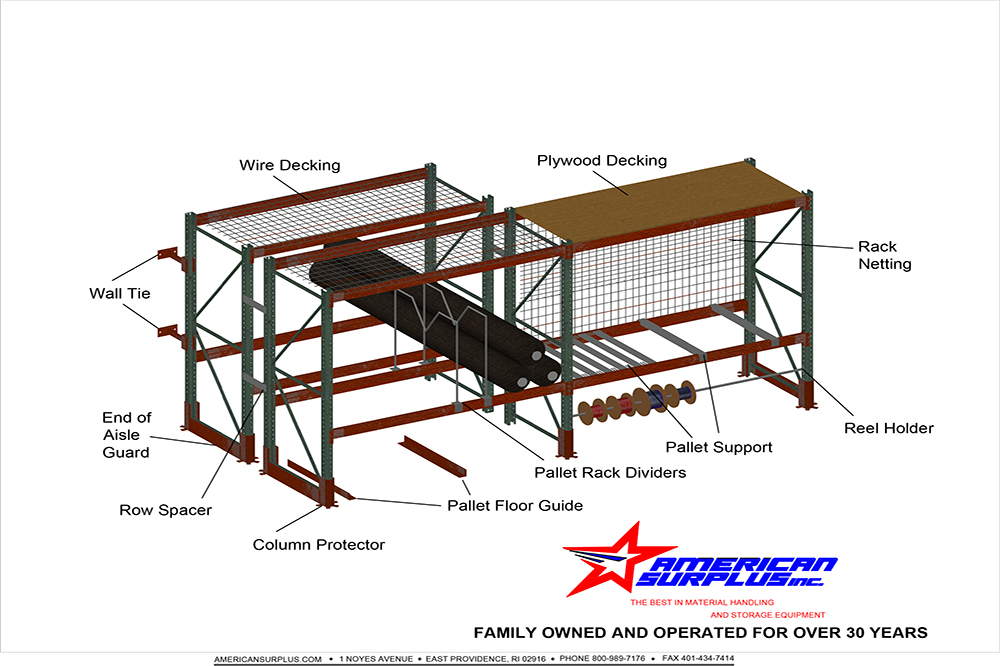

American Surplus offers customization options to tailor your teardrop pallet rack system to your specific needs. This can include selecting different beam lengths, frame heights, and accessories like wire decking or safety features. Known for offering competitive prices on both new and used teardrop pallet racks. This affordability can make it an attractive option for businesses looking to maximize their storage space within a budget. American Surplus has experts who can provide consultation and recommendations to help you select the right teardrop pallet rack system for your specific storage needs.