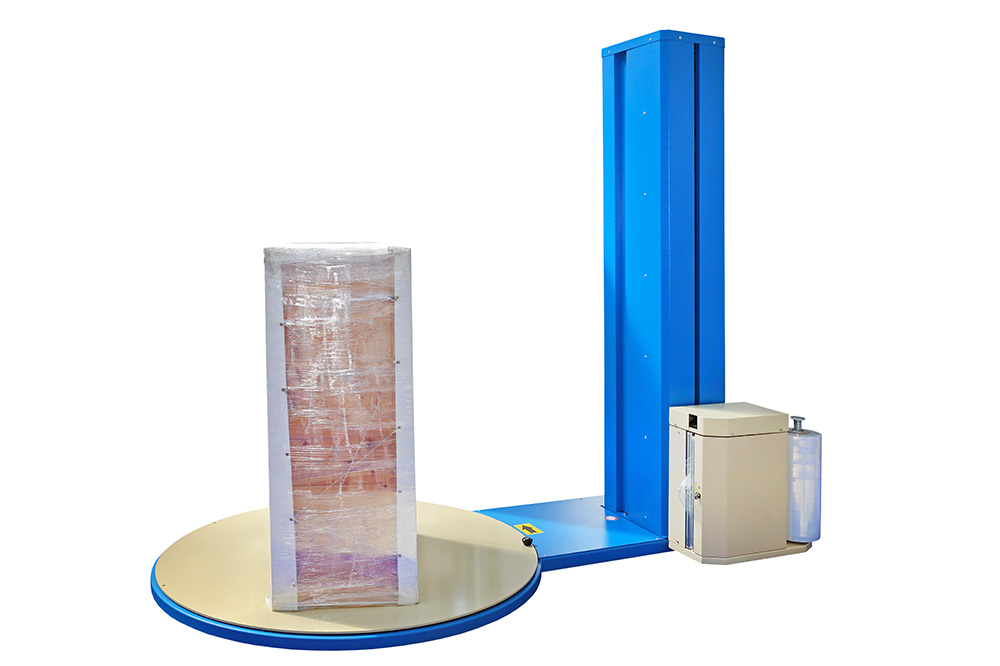

Stretch wrappers are often used to package a load of products, usually on a pallet, tightly and securely so items won’t move during distribution and storing. Stretch wrap is a plastic film that delivers exceptional protective tension. This protective wrap significantly improves load stability when in transportation. By improving the stability of the load, you create it easier to transport and ship. It also shields individual products from being damaged. Wrappers can also help increase throughput capabilities so that a facility can operate at its most efficient capacity. Using these helps to reduce film consumptions resulting in lower film costs.

Stretch wrapping equipment has multi-purpose functions such as keeping a load stable and protecting packaged inventory/products. There are many advantages of wrapping your products and inventory with a stretch wrapper such as:

- Protection of Goods from Damage, Dust and Moisture

- Increase Productivity and Efficiency of Employees and Facility

- Efficient Product Wrapping

- Reduce Product Damage

- Better Inventory Control

- Increase Throughput Capabilities

- Stretch Films are 100% Recyclable

- Reduce Film Consumption

- Lessen Repetitive Motion Injuries

- Reduce In-Transit Damage

- Improved Load Stability

- Decrease Labor Costs

Stop wasting money on inconsistent packaging. Call a knowledgeable sales associate today at (800) 876-3736 or request a quote online.

How to Choose a Stretch Wrapper

Choosing a stretch wrapper depends on several factors such as the size and shape of the load to be wrapped, the production rate, the type of stretch film used, and the level of automation required. Here are some steps to help you choose a stretch wrapper:

- Determine the load size and weight: Measure the size and weight of the loads you want to wrap. This will help you choose a wrapper with the right size and capacity.

- Consider the load shape: If your loads are irregularly shaped or have protrusions, you may need a stretch wrapper with a custom wrap program.

- Determine the production rate: The speed at which you need to wrap the loads will determine the type of wrapper you need. A high-volume facility may need an automatic stretch wrapper, while a smaller operation may need a semi-automatic or manual wrapper.

- Decide on the type of stretch film: There are several types of stretch film available, including cast film, blown film, and pre-stretched film. The type of film you choose will affect the wrapper you need.

- Consider the level of automation: An automatic stretch wrapper can significantly improve efficiency and productivity. However, it may be more expensive than a semi-automatic or manual wrapper.

- Think about maintenance and support: Ensure that you choose a wrapper that is easy to maintain, and has good technical support available in case of any issues.

- Consider the budget: Finally, consider the cost of the wrapper and determine whether it fits within your budget.

By considering these factors, you can choose a stretch wrapper that meets your specific needs and improves your wrapping efficiency.