Pallet rack accessories are a critical component of any warehouse or distribution center that uses pallet racks. These accessories can help improve the safety, organization, and storage capacity of pallet racks. There are many different types of pallet rack accessories available on the market today, each with its own unique set of benefits and features.

The reason pallet racking accessories are so important is because they increase the stability and safety of the pallet racking system. These accessories significantly reduce the risk of pallets falling and warehouse employees getting severely injured. Aside from improving the pallet racking system these accessories can be used to make the pallet rack to better fit the owner’s needs.

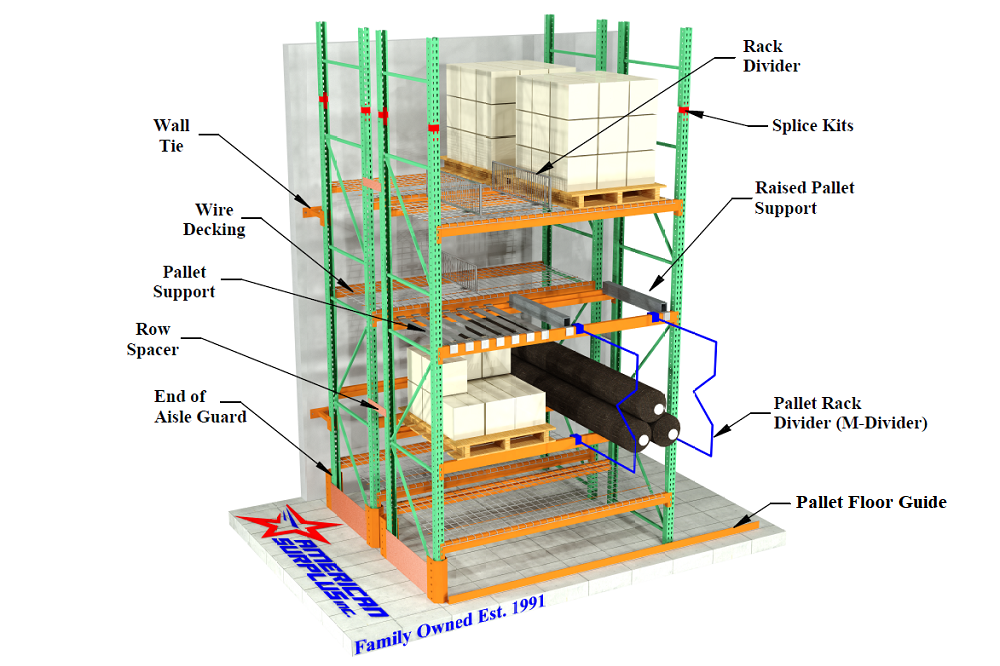

Some of these pallet rack accessories are OSHA required and RMI recommended. Some of the other accessories ASI carries for your pallet rack are row spacers, pallet supports, skid channels, end of aisle guards, m-dividers, wire decking, corrugated decking, wire deck dividers, splice kits, floor anchors, wall ties, column protectors, reel holders, safety netting, pallet stops, and bull nose protection.

If you have questions about what type of pallet rack accessories are best for you. With over 30 years in the material handling industry let our knowledgeable sales staff help. Give us a call today at (800)876-3736 to speak with a member of our sales team about your pallet racking needs today! American Surplus will provide a quote on new equipment if used is unavailable.